Laboratory Equipments

Drop tower:

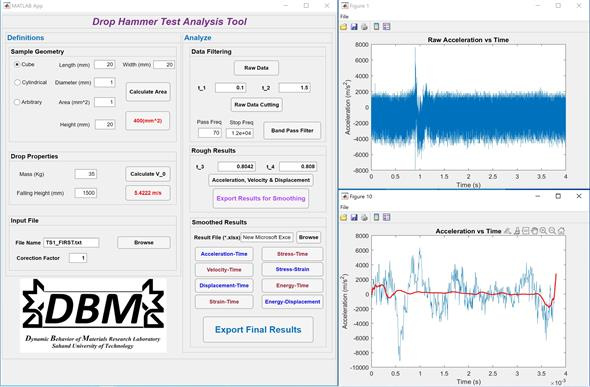

Drop tower or drop weight test rig is used to determine the energy required to break or crush test specimens suchas laminates, composites, ceramics and metals for material and component evaluation to international testing methods such as ISO6603, ISO3127 and ASTM D2444 to name a few.

The apparatus is extremely multifunctional. The standard machine is supplied with a 4 meters variable drop height system which can reach impact velocities up to 8.85 m/s. With an impact energy range of up to 2000 joules. A twin guide rail system is used to ensure a smooth repetitive drop of the load carrier perpendicular to the sample being tested. Load carriers are available for different energy ranges and are fitted with low friction bearing guides which prevent velocity and potential energy being lost as the carrier descends. Impact tups are supplied to international test standard methods, or to customers own individual requirements, which can simulate the mode of failure in actual service conditions or to analyses specific in-house quality control standards

Hopkinson:

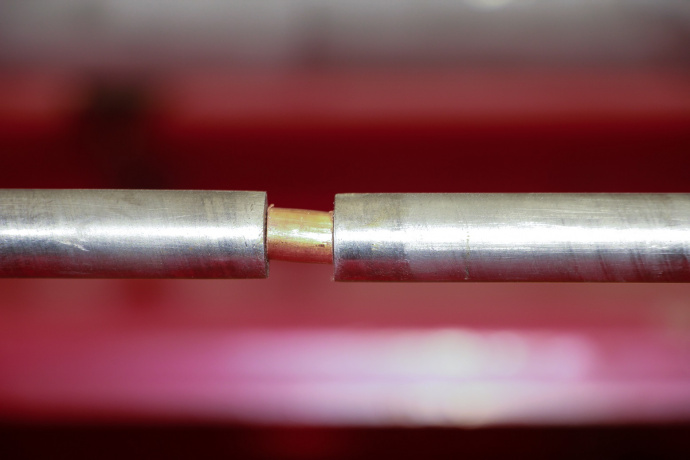

A Split Hopkinson Pressure Bar (SHPB) is used to test the high strain rate material properties of materials. The Hopkinson bar is used to impose a dynamic load on a material specimen akin to that which the material will experience in dynamic situations like vehicle crashes or other high-energy events.Split Hopkinson pressure bars, or Kolsky bars, can be miniaturized to achieve very high strain-rates, and rates in excess of 1,000,000/s have been achieved.

A Split Hopkinson Pressure Bar / Kolsky Bar system will contain a precision accelerator, an incident bar, a transmission bar, and a stopping mechanism that are aligned and mounted on a REL flat base.

The accelerator is charged with pressurized gas to accelerate a striker bar at a measured velocity to create an impact incident. Striker bars of various lengths are used to produce a range of loading durations i.e. short striker bars impart short time duration loads. The impact of the striker bar on the incident bar sends a stress pulse traveling down the incident bar (at the speed of sound) that is detected by a strain gage mounted on the bar.

In DBM, for material assessment in higher loading rates, a Split Hopkinson Pressure Bar (SHPB) which enjoys a 1 MHz data logger would examine specimens’ behavior with maximum of 900 Mpa yield stress.

Single-stage gas guns

Single-stage gas guns are commonly used for medim velocity launches and for applications requiring highly reproducible performance. Single stage gas guns are the launchers of choice for conducting high precision planar impact experiments.

DBM single-stage light gas guns are the practical devices for launching projectiles at velocities over 2,50 m/s with compressed air.

.