Open Cell Aluminum Foams

Open-cell Alumiuim foams have various benefits and drawbacks, as well as a wide range of applications. Here's how it works:

Benefits of Open-Cell Aluminum Foams:

1. Lightweight: Because open-cell aluminum foams have a high porosity, they are significantly lighter than solid aluminums. This makes them perfect for applications requiring significant weight reduction, such as the aircraft and automobile industries, where fuel efficiency and maneuverability are vital.

2. High Energy Absorption: Aluminum foams' open-cell structure allows them to absorb and dissipate energy effectively, making them great materials for impact and crash protection. They have the ability to absorb and distribute energy, which reduces the force transferred to protected items or individuals.

3. Thermal and acoustic insulation: The open-cell aluminum foams' interconnected porosity traps air or other gases, giving excellent thermal and acoustic insulation. Because of this, they are excellent for applications requiring heat transfer or noise reduction, such as building construction, HVAC systems, and industrial noise control.

4. Increased Surface Area: Aluminum foams have a larger surface area than solid aluminums due to their open-cell structure. This enhanced surface area is excellent for applications requiring a high surface-to-volume ratio, such as catalysis, filtration, heat exchange, and electrode materials for energy storage devices.

5. Pore Structure Can Be Customized: The porosity and pore size of open-cell aluminum foams can be adjusted to individual application needs. Because of this customization, features such as permeability, stiffness, and energy absorption may be fine-tuned, making them ideal materials for a variety of applications.

Open-Cell Aluminum Foams Have the Following Drawbacks:

1. Lower Mechanical Strength: Because of their porous structure, open-cell aluminum foams have lower mechanical strength than solid aluminums. As a result, its usage in applications demanding great structural integrity or load-bearing capability may be limited. However, developments in foam manufacturing techniques have resulted in stronger properties.

2. Limited Material Options: When compared to solid aluminums, the variety of aluminums that can be properly foamed is fewer. Because not all aluminums and alloys are easily foamable, the selection of materials for specific applications may be limited.

Open-Cell Aluminum Foam Applications:

1. Open-cell aluminum foams are extensively used in protective equipment such as helmets, body armor, and vehicle crash pads to absorb and distribute impact energy, lowering the risk of damage.

2. Thermal Management: Because of their high surface area and thermal conductivity, open-cell aluminum foams are ideal for use as heat sinks, heat exchangers, and cooling systems in a variety of industries, including electronics, power generation, and automotive.

3. Acoustic Insulation: Open-cell aluminum foams are used to limit noise transmission and improve acoustic comfort in architectural soundproofing, industrial noise control, and automotive applications.

4. Filtration: The porous nature of open-cell aluminum foams allows for efficient air, gas, and liquid filtration and separation operations, making them valuable in applications such as water treatment, air purification, and industrial filtering systems.

5. Open-cell aluminum foams can be utilized as electrodes for energy storage devices such as batteries and supercapacitors, as well as catalyst supports for energy conversion systems such as fuel cells.

6. Aerospace and Automotive: Because of its lightweight nature, energy absorption capabilities, and thermal management features, open-cell aluminum foams find uses in the aerospace and automotive sectors. They are found in structural parts, crash absorbers, and heat exchangers.

These benefits, drawbacks, and applications highlight the distinct qualities and potential of open-cell aluminum foams in a variety of industries where lightweight, energy absorption, temperature management, and filtration are critical considerations.

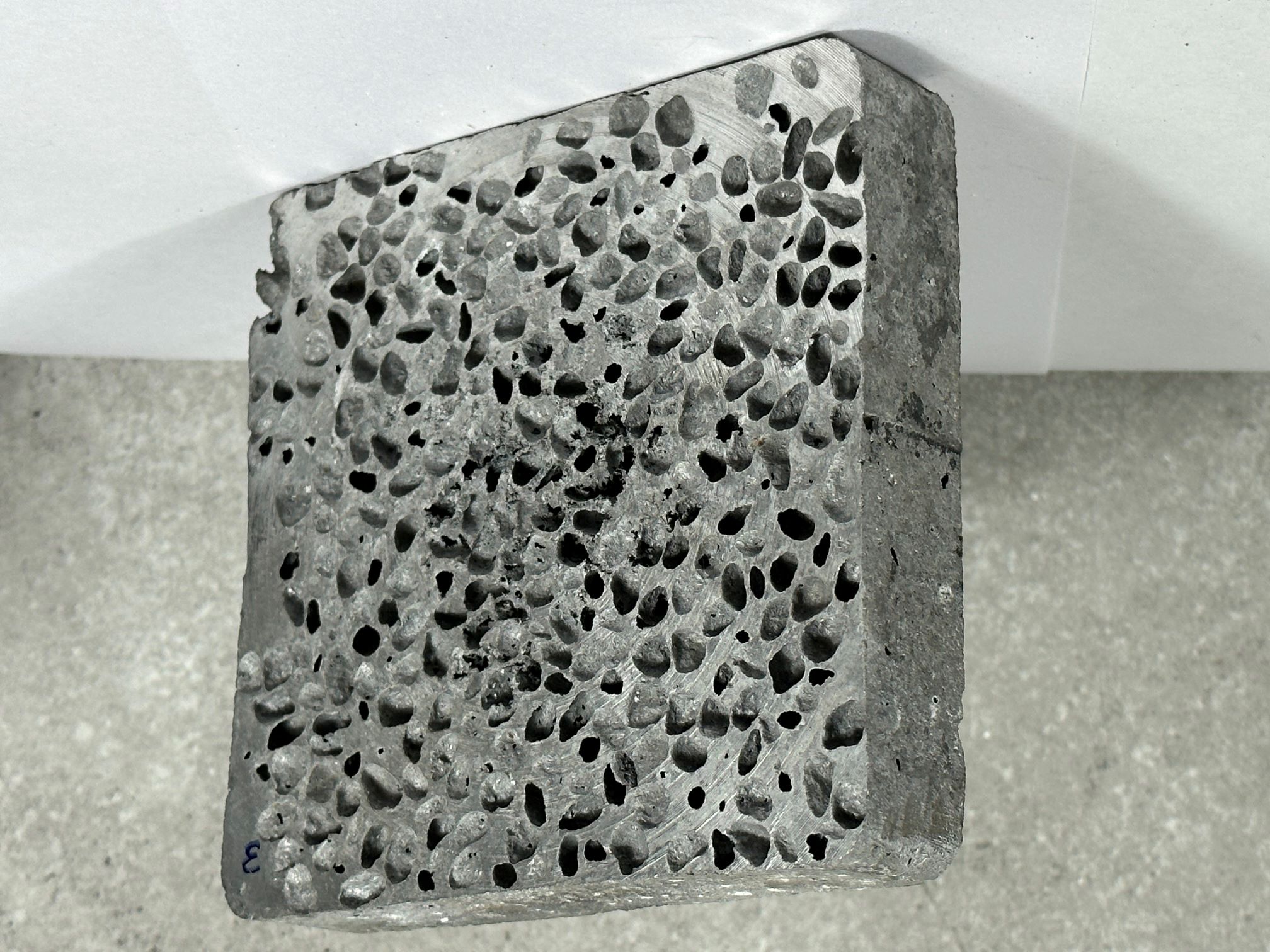

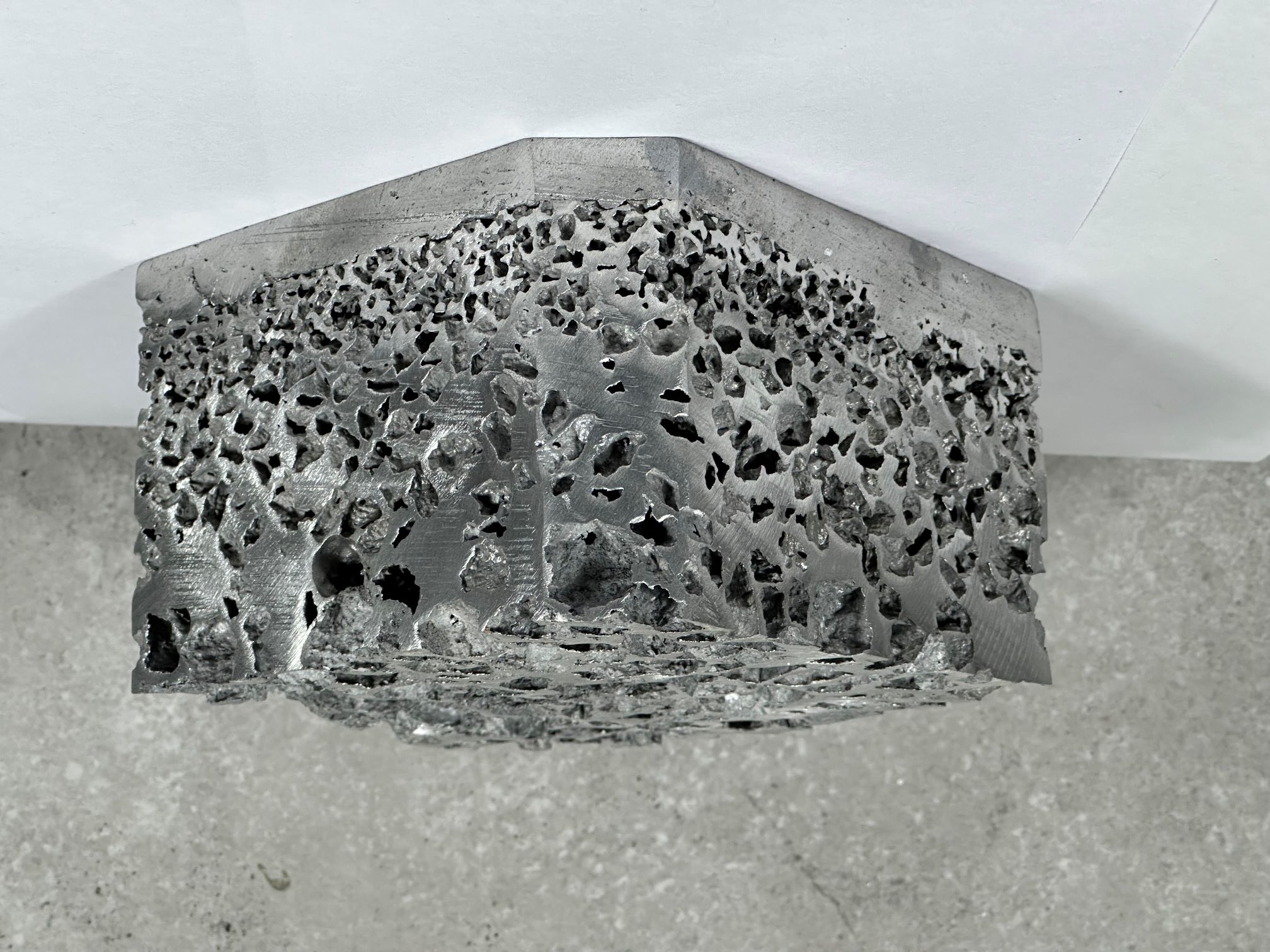

The Dynamic Behavior of Materials Research Laboratory can produce aluminum-based open-cell foam in a variety of cavity shapes and sizes. It can, however, produce aluminum foam structures with planned holes of various sizes and shapes throughout the sample's height. It also enables the continuous integration of bulk materials with porous media, opening up new material design options.